Wastewater Treatment Plant

Odor issues and biosolids were effectively reduced by application of Bio 10V

Odor & Solids Reduction – Waste Water Treatment Plant

Problem

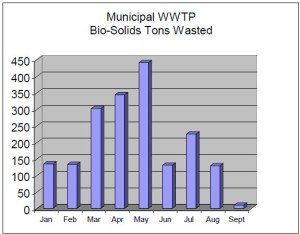

A wastewater treatment plant (WWTP) in Southeast Georgia located on a resort island has a 3 million gallon per day flow. The WWTP was experiencing major odor problems at the head of the plant, as well as poor digestion and settling of bio-solids in the SBR’s and aerobic digesters. The odors were primarily H2S and were the source of numerous complaints from the residents living in the vicinity of the WWTP. The plant was hauling and disposing an average of 125 to 150 tons of bio-solids per month at a cost of approximately $60 per ton, which equates to $7,500 to $9,000 total average hauling/disposal charges per month.

Solution

Bio 10V was added to the influent of the wastewater stream approximately 100 yards before the head of the plant. The product was added at a rate of 3-4 PPM of the daily flow (3 million gallons). Odors were immediately reduced at the head of the plant. Within 2 days the plant operator began to see a significant reduction in solids in the SBR’s as well as the digesters.

The WWTP was treated for a period of 30 days at a rate of 3-4 PPM. The plant operator also added 2.5 gallons of product directly into the digesters each day.

Conclusion

During the first month of treatment the odors being generated at the head of the plant were dramatically reduced. No odor complaints from the residents were received during the first month of application. The total wasted solids for the 30 day period were reduced from an average of 125 to 150 tons to 2 tons (98.4% reduction). The plant saved $7,380 in hauling/disposal expense during the month. The improvement in overall plant operation also allowed for fewer man hours being needed to run the plant.